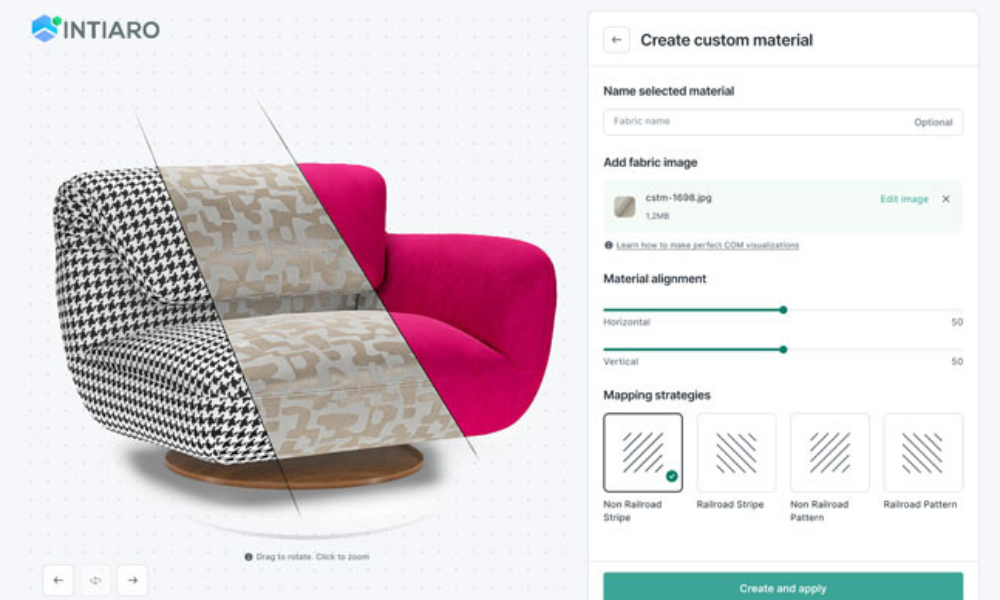

Intiaro has introduced a new 3D tool designed to streamline the custom furniture manufacturing process. The customer’s own material visualization tool allows manufacturers to showcase any customer-specified fabric or leather on furniture designs in real time without requiring specialized 3D skills.

According to Intiaro, this tool is expected to accelerate the high-margin COM business by reducing errors, improving lead times and increasing the number of completed projects. The result is a higher return on investment for furniture manufacturers.

“We are solutions providers first and developers second, and our COM solution is in direct response to what we identified as a common challenge among our current and potential clients,” says Michal Stachowski, CCO and co-founder of Intiaro. “COM is often one of the highest margin sales areas, and our tool addresses friction in the process.”

The web-based tool can be accessed directly from a manufacturer’s website, allowing designers and customers to apply custom materials to furniture and see the results instantly. This eliminates guesswork and minimizes the risk of costly errors or returns. No technical background or training is required to use the tool, making it accessible for a broad range of users.

One of the tool’s key features is the ability to download customized furniture models in multiple 3D formats and quality levels. These models can be integrated into floor plans and larger design visualizations, providing additional value for tech-savvy users.

“Our COM solution can shorten the design and communication cycle for manufacturers, designers and their clients by up to 10 times,” adds Stachowski. “Clients today expect personalized products, and this tool allows manufacturers to scale customization without adding complexity, ensuring more business and better margins.”

Intiaro is demonstrating the new COM tool at the High Point Market, where the team is available for appointments to showcase its latest solutions.